6 Sigma | Lean (DMAIC) is a data-driven, factual improvement methodology.

It can generate very significant benefits – tens of millions of dollars per year in some industries – when it is applied to issues that are:

- Important and costly

- Must be fixed correctly, the first time

- Where a solution is not generally agreed and / or obvious.

6 Sigma / Lean should not normally be applied to problems that can be fixed via low-cost trial changes, or where the benefits of resolving an issue are minimal. In these cases the cost of applying

6 Sigma / Lean may outweigh the benefits.

Like all tools, applying it at the right time and in the right place makes best use of the tool.

Below are frequently asked questions raised by Management.

- Can we use lean or Six Sigma alone?

- Shall we use Lean and Six Sigma together?

- If we want to adopt Lean and Six Sigma together, how?

- Which one goes first?

- How will we know if we’re doing it right?

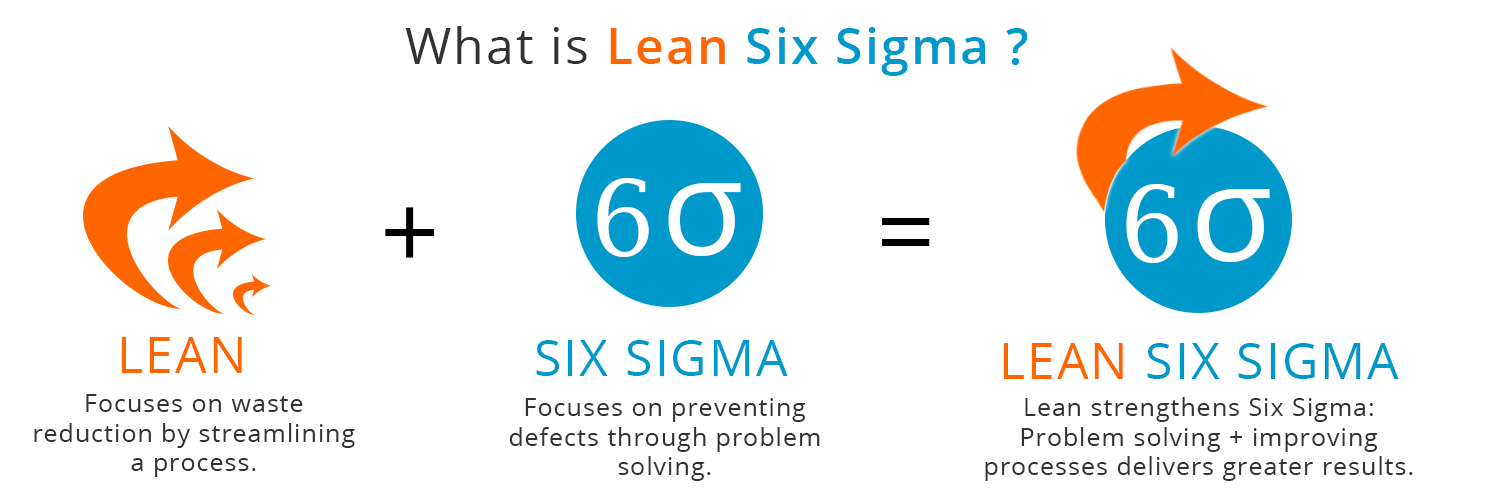

Lean tools are traditionally developed by Industrial Engineering to improve productivity and eliminate wastes while Six Sigma tools are originally used by Quality Engineering to improve quality, reliability and defect level of products and services.

The barrier of these two engineering disciplines are diminishing slowly and both are converging into a new powerful and practical discipline, namely as Lean Six Sigma in general and Lean-Sigma Power-Plan and Service Lean Sigma and Lean Sigma Design under our own corporate services.

Past regarding Lean and 6 Sigma was

Lean. Focused in eliminating non-value added waste in a process with goal of reducing process cycle times, improving on-time delivery performance and reducing cost.

Six Sigma. Using statistical techniques to understand, measure and reduce process variation with the primary goal of achieving improvements in service quality and cost.

The today approach meaning

Lean Six Sigma. Is today an integrated and balanced combination of the speed and variation reduction power of both Lean and Six Sigma to achieve business management process full optimization.

Six Sigma is deployed mainly for innovative, breakthrough and continual improvements under the black belt projects led by Black Belts and Master Black Belts while Lean is deployed mainly for daily continual improvements and performance sustaining activities under the lean Kaizen events led by Line Engineers and Supervisors.